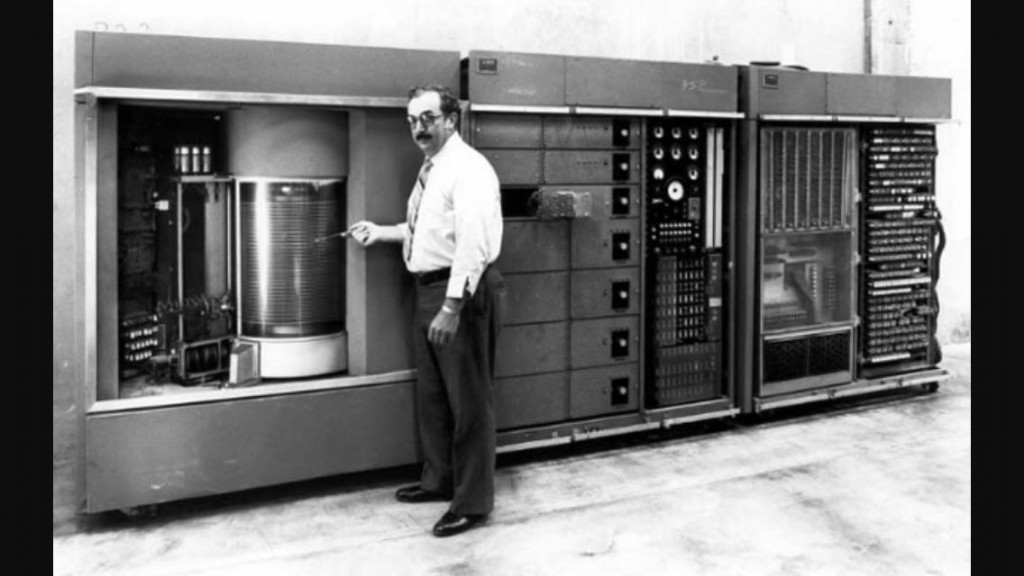

We are almost a quarter of the way through the 21st century and those of us who were around 50 years ago couldn’t have imagined the speed at which technology and change would happen.

In fact, most of us have no way of knowing what amazing breakthroughs are just around the corner. Innovation is moving at light speed. In fact, I was having a conversation with an executive with a large Defense Contracting company about new product development and the future, and he stated, “that if you can imagine a future product, we have already invented it”. Now, that can be scary, or it can be exciting. For business, it is exciting.

Technology touches all aspects of our lives, and we rely on it to assist us in our personal lives and our business lives. We can’t function without it, and most of us get excited about the next new ‘thing’.

Businesses are no different. They are constantly bombarded by new IT, and new faster equipment. Their desire is to access production information that allows them to build products faster, with higher quality. It also allows them to make more accurate day-to-day decisions as well as can assist in making strategic decisions. The goal is the technology, or equipment, will allow them to service their clients better while making them more competitive.

Investing in technology, or new equipment, are options every business needs to investigate. They need to determine if the investment will take them to the next level of efficiency, success, and growth. But prior to investing in the new technology, the leadership needs to first understand the impact the investment will have on their bottom-line, and does it support/enhance the end-to-end process.

If the investment is to resolve a bottle-neck in the current process, you should first ask if you’re inserting it into an inefficient end-to-end process – one that could be improved for productivity and capacity utilizing your existing resources. There is an old saying ‘Don’t pave the cow path’. Putting technology into a process that is full of waste, makes it very difficult to build an accurate business case with an understanding of what you need, and how much of it you need, to drive you to the next level of profitability in the future. And in most cases, it solidifies the ‘waste’ in the system.

Making an investment today that you will likely have for decades requires an understanding of your future needs. You can’t do this without at least understanding what the future state of your processes are to meet your ever-changing customer demands. We urge to maximize the potential of your current process, or at least understand the potential, and then determine what technology, and just as important how much of the technology, you require to support the process(es). Don’t fall into the trap of having the processes support the technology.