Workshop Focus:

This workshop is designed primarily to provide a practical Introduction to Lean tailored specifically for individuals directly involved in continuous improvement activities. At the conclusion of the workshop participants will have an understanding of Lean as a client-centered philosophy that combines a proven methodology to lead continuous improvement teams. You will have the understanding of how to successfully select and engage the appropriate team to properly identify and improve processes within your area of responsibility. Lean will support efforts to effectively enhance service delivery to your clients / customers / members with greater quality and at the least cost.

Who Should Attend?

Individuals and organizations looking to support their continuous improvement efforts through the use of Lean Methodologies, thinking and tools:

- Leaders

- Managers

- Supervisors

- Continuous Improvement specialists

- Quality specialists

Topics include the following:

- The Philosophy of Lean

- 9 Types of Waste (Includes interactive brainstorming exercise)

- Value Added Work vs. Incidental Work vs. Pure Waste

- Fundamental 5 Lean Principles (Includes interactive simulation to reinforce Lean Principles)

- Lean Tools – Sample list below:

- Value Stream Mapping

- 5S Workplace Organization

- Visual Controls

- Mistake Proofing

- Kanban, Supermarkets

- Flow Cells

- Kaizen – Rapid Improvement Events

- Define and select Value Streams for improvement

- Creating Value Stream Charters

- How to select a Value Stream Team

- Determining success measures

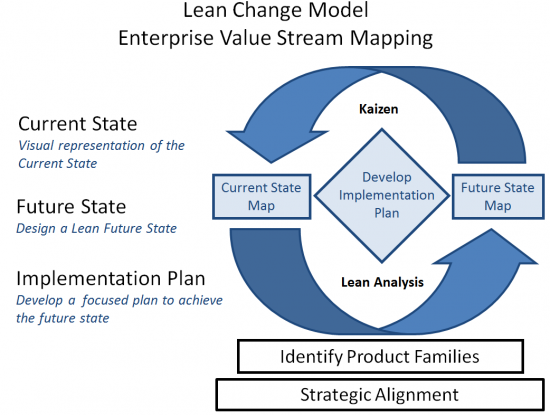

- Completing a Value Stream Map

- Determine Service / Product Family

- Current State Map

- Future State Map

- Implementation Plan

- Conducting Kaizen, Rapid Improvement Events

- Completing a Kaizen Charter

- Selecting Kaizen Team

- Determine measure of success

- Methodology to conduct a Kaizen event

- Report outs to sponsors and key stakeholders

Workshop Agenda: Day 1

| 09:00 | A. Getting Started: Welcome and Objectives B. Lean origins C. Waste Definitions |

| 10:30 | Break |

| 10:45 | D. Waste Exercise E. Lean Simulation Round 1 |

| 12:00 | Lunch |

| 12:30 | F. Principles of Lean G. Lean Tools • Value Stream Mapping • 5S Workplace Organization • Visual Controls • Mistake Proofing • Kanban, Supermarkets • Flow Cells • Kaizen – Rapid Improvement Events |

| 14:00 | Break |

| 14:15 | G. Lean Tools complete H. Lean Simulation Round 2 |

| 15:30 | Open Forum Q & A |

| 16:00 | Workshop Close Day 1 |

Workshop Agenda: Day 2

| 09:00 | A. Getting Started: Day 1 Review and Day 2 Objectives B. Introducing Value Stream Mapping as a critical Lean tool C. Selecting Value Streams |

| 10:30 | Break |

| 10:45 | D. Value Stream Mapping. Team Exercise • Select team members for a Value Stream Exercise • Completing a Charter Document Waste Exercise • Create a Current State Map • Conduct a Current State Lean Analysis • Create a Future State Map • Complete an Implementation Plan |

| 12:00 | Lunch |

| 12:30 | E. Value Stream Team Report Out F. Lean Simulation Round 2 G. Linking Kaizen to Value Stream Mapping |

| 14:00 | Break |

| 14:15 | H. Conducting a Kaizen Event • Selecting Team members for a Kaizen Event • Completing a Kaizen Charter • Linking success measures back to the Value Stream • Follow a problem solving model to complete a Kaizen • Identifying Lean tools to support your Kaizen I. Group discussion on what your next steps should be |

| 15:30 | Open Forum Q & A / Workshop Evaluation |

| 16:00 | Workshop Close Day 2 |

Facilitator:

Mike Boucher, Senior Lean Consultant and Trainer

Lean Advisors, Inc., a member of the Intersol Group of Companies

Mike has over 25 years’ experience with Lean in his role leading companies in their Continuous Improvement and Lean journeys. Throughout Canada and the US, he initiated and perfected the application of this knowledge and experience within government, crown corporations, healthcare (hospitals, laboratories, and administration), and educational environments, in addition to traditional private sector manufacturing settings.

Enrolment is Limited on Purpose!

In order to ensure as much personalized attention, interaction and learning, each workshop will be limited to a maximum of 15 participants.

Investment: $995.00 + HST Includes workshop workbook, refreshment breaks and lunch.